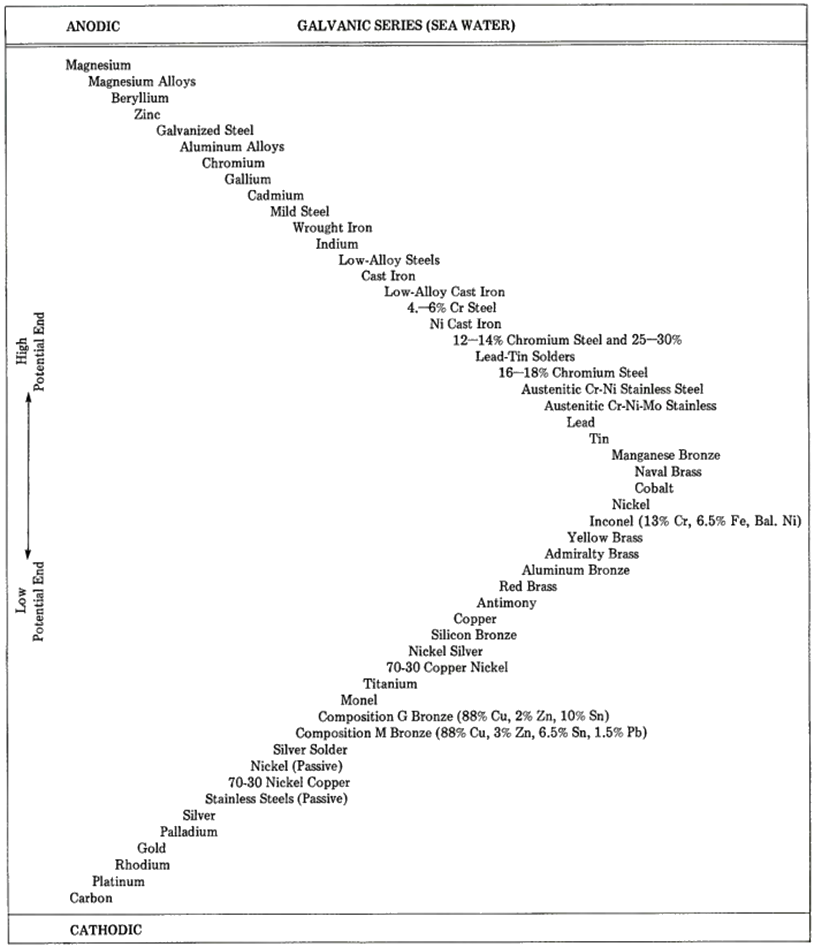

A common form of corrosion occurs between dissimilar conductive material types. These materials include all metals and carbon fiber laminate. The extent or severity of the reaction between different materials depends on the position relative to each other on the galvanic series. The further apart the two materials are the greater their propensity to galvanically corrode.

The galvanic series is given in the figure below:

AGARD-AG-278, 1985)

AGARD-AG-278, 1985) It follows that direct contact of materials from different ends of the galvanic series should be avoided.

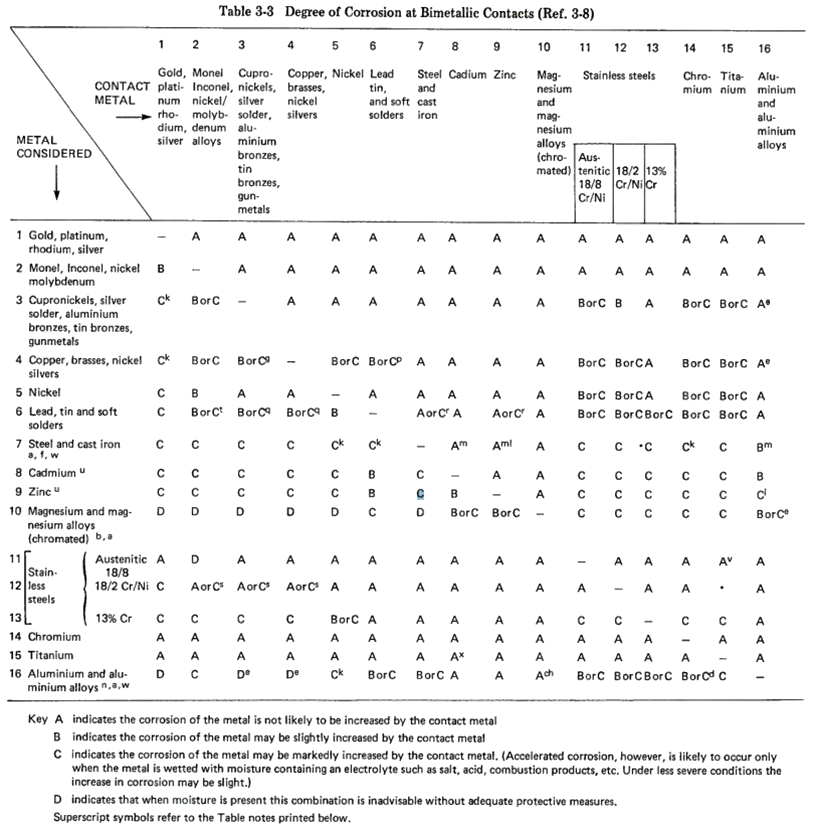

The following figure gives the appropriate level of concern and mitigation required for common material combinations.

AGARD-AG-278, 1985)

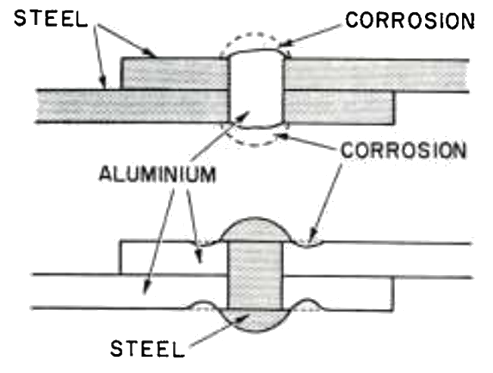

AGARD-AG-278, 1985) The most common cause of galvanic corrosion is a dissimilarity in metals at fastener locations. The form of this corrosion is shown below:

AGARD-AG-278, 1985)

AGARD-AG-278, 1985) 4.4.5.1. Use of Sealants to Mitigate Galvanic Corrosion

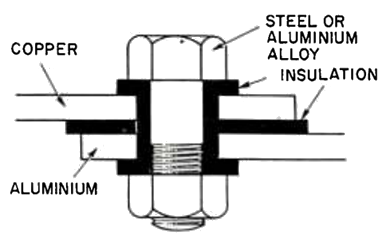

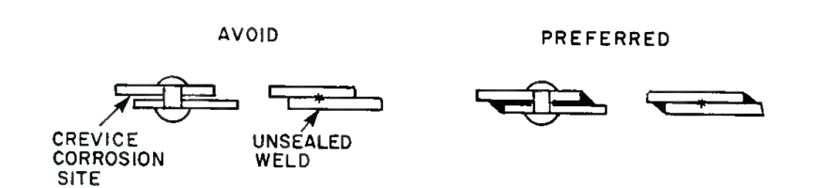

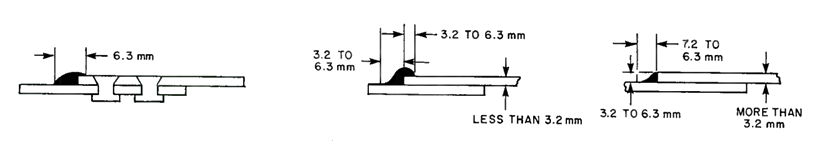

Where dissimilar materials are used at mechanically fastened joints it is important to ‘wet’ install the fastener using a sealant. It is also important to seal the joint to avoid moisture entering by other means.

AGARD-AG-278, 1985)

AGARD-AG-278, 1985) The behavior of aluminum fasteners in carbon fiber laminate is similar and tends to be more severe.

Figure 4.4.5‑5: Sealing of Joints Against Moisture Ingress (

AGARD-AG-278, 1985)

AGARD-AG-278, 1985) 4.4.5.2. Galvanic Corrosion Recommended Protective Treatments (in order of effectiveness)

This information is taken primarily from (![]() MIL-STD-889C, 2016).

MIL-STD-889C, 2016).

Treatments For Magnesium:

- Anodic coating (ASTM D1732) post treated with an alkali-resistant paint or resin coating system.

- Chromate conversion coating (SAE AMS-M-3171) post treated with an alkali-resistant paint or resin coating system. Alternate for general use in non-persistent wet or marine atmosphere; or anodic coating without organic coating system.

- Metallic coating, electroless nickel (SAE AMS-C-26074, or MIL-DTL-32119 where applicable) with cadmium overplating (SAE AMS-QQ-P-416). For electrical, thermal conducting purposes, in absence of wet, saline or acidic atmospheric conditions.

- Chromate treatment. Suitable for assured condensation-free and acid-free conditions.

Note: Bare magnesium should not be used.

Treatments for Zinc:

- Anodic coating post treated with a paint or resin coating system, primarily for castings.

- Chromate conversion coating (MIL-C-17711) post treated with a paint or resin coating system; or anodic coating without organic coating system. For use in non-persistent wet or marine atmosphere. For electrical, thermal conducting purposes in mild atmospheres in absence of wet, saline or acidic conditions.

- Chromate conversion coating without paint or resin coating system.

Note: Bare, plated zinc should not be used in a marine environment.

Treatments for Cadmium or Beryllium:

- Chromate conversion coating (SAE AMS-QQ-P-416, SAE AMS-C-8837 or SAE AMS-C-81562) post-treated with a paint or resin coating system.

- Chromate conversion coating without organic coating system. For use in non-persistent wet or marine atmosphere. For electrical, thermal conducting purposes in mild atmospheres in absence of wet, saline or acidic conditions. Recommended for beryllium in high temperature applications to forestall catastrophic oxidation in oxygen containing atmosphere.

Treatments for Aluminum and Aluminum Alloys:

- Anodic coating (MIL-A-8625) post treated with a paint or resin coating system.

- Chromate conversion coating (MIL-DTL-5541) post treated with a paint or resin coating system; or anodic coating, sealed, with resin seal (when porous castings are used, impregnated with resin prior to surface treating and finishing).

- Chromate conversion coating without paint or resin coating system, for electrical, thermal conducting purposes in mild atmospheres in absence of saline, alkaline or acidic conditions.

- Bare aluminum – may be used when surface treating would interfere with application, under conditions free of salinity or extended wetness, or when high corrosion resistant alloys are used. Faying edges should be sealed to prevent crevice corrosion.

Treatments for Carbon and Low Alloy Steels:

- Metallic coating (e.g., sacrificial Zn or Cd, with supplemental passivation or surface treatment or non-sacrificial, e.g., Cu or Ni), with a paint or resin coating system. For steels of strengths greater than 220ksi metallic coatings should be applied by nonelectrolytic methods. For steels of strengths up to 220ksi metallic coatings may be applied electrolytically, but the steel should be stress relieved before plating and hydrogen embrittlement relieved after plating.

- Metallic coating (e.g., sacrificial Zn or Cd, with supplemental passivation or surface treatment or non-sacrificial, e.g., Cu or Ni), without paint or resin coating system, for direct metallic contact or for achieving least potential difference between joined metals. For metals of strengths greater than 220ksi, metallic coating, if required, should be applied by non-electrolytic methods.

- Zinc phosphate conversion coating (TT-C-490) post treated with a paint or resin coating system. Caution, if a phosphate coating is used on steels of strengths between 150 to 220ksi, stress relief is required prior to phosphating and hydrogen embrittlement relief is required after phosphating. Zinc phosphate coatings are prohibited for steels of strength greater than 220ksi.Pretreatment primer (MIL-C-8514) post treated with a paint or resin coating system.

- Heavy phosphate conversion coating (MIL-DTL-16232) post treated with a supplemental treatment. Not for steels of strengths greater than 220ksi.

Treatments for Lead, Tin Solders and Indium Coatings:

Coatings of these materials applied to other metals by hot-dipping, fusing, or electroplating processes.

- Coat with paint or resin coating system. Electroplated coatings should be “flowed” prior to applying coating system.

- Electroplate with other metal to reduce the electro potential difference of metals being joined, where direct contact of metals is required for electrical purposes.

Treatments for Martensitic and Ferric Stainless Steels:

Steels with chromium contents in the region of 12 percent will undergo considerable surface staining and limited rusting in corrosive environments, but overall are appreciably less corroded than carbon steels.

- Apply paint or resin coating system.

- May be electroplated or used bare for use in non-persistent wet or marine atmosphere, and for electrical or thermal conducting purposes. Faying edges to be sealed to prevent crevice corrosion.

Treatments for Chromium (Plate), Molybdenum and Tungsten:

- Paint or apply resin coating system to reduce corrosion at voids in chromium plating or staining of molybdenum or tungsten surfaces.

- Normally may be used bare for electrical wear resistance, or thermal conducting purposes. Seal faying edges to mitigate crevice attack.

Treatments for steels stainless-austenitic, PH, super strength, heat resistant, brass leaded, bronze, brass bronze-low copper, and copper high nickel:

- Apply metallic coating as may be required to minimize electrical potential difference between the metals to be joined and apply paint or resin coating system, primarily to diminish ion contamination from metals of this group onto more anodic metals to which they might be joined, thereby diminishing potential damage to the more anodic metal.

- Apply metallic coating (as “a” above), use without paint or resin coating system, for electrical or thermal conducting purposes. May be expedient to overcoat completed assembly with paint or resin.

- Apply paint or resin coating system and seal faying edges.

- Use bare and seal faying edges for electrical and thermal conducting purposes, if more anodic metals are not directly joined or in close proximity to receive rundown of surface condensate.

- Select galvanically compatible metals required to be coupled for high temperature applications, where metallic coatings may not be useful and paint or resin coatings are not practical.

Treatments for Titanium:

- Anodize, for anti-galling and wear resistance.

- Apply metallic coating (Cd, Zn prohibited, Ag over Ni acceptable) post-treated with a paint or resin coating system.

- Apply metallic coating (Cd, Zn prohibited, Ag over Ni acceptable), seal faying edges. For electrical or thermal conducting purposes.

- May be used bare with faying edges sealed in contact with metals other than magnesium, zinc or cadmium; for electrical or thermal conducting purposes.

Treatments for Silver:

- Silver or silver plated parts to be used as electrical, open-close contact points, plugs and receptacles should be plated over with rhodium, palladium or gold.

- May be used in stationary components of electrical assemblies, e.g., connectors, printed circuits, but should be enveloped by sulfur-free conformal coatings.

- Apply chromate conversion coating post treated with a corrosion inhibiting fluid film to parts of electrical plugs, receptacles, etc.

Treatments for rhodium, palladium, gold, platinum and alloys:

Use bare, with compound sealant at edges of dissimilar metal joint, or by enveloping dissimilar metal joint in conformal coatings, where feasible.

Treatments for Graphite:

- Plate graphite to minimize electrical potential difference between graphite and metal to be joined to it. Seal faying edges to preclude corrosion at contacting surface of the metal member, if service is electrical, or apply conformal coating.

- . May be used bare in electrical or thermal conducting service, conditions permitting. Seal faying edges.