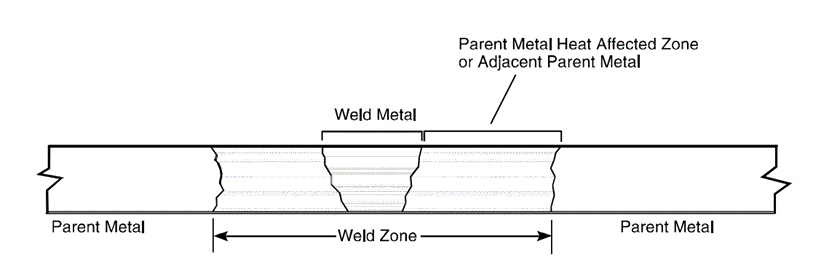

Welding two pieces of like metal together will result in a joint that contains the following elements:

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998) Like any other design feature the actual strength of the feature depends on how well the assembly is designed for manufacture. Consultation between the engineer and the welder is a very good idea and will help both the designer and analyst avoid either designs that are likely to fail in service or designs that require rework in manufacture.

Where possible, welded joints should be designed to carry shear load rather than tension load.

In general, the information in this section is applicable to TIG welded joints.