The analysis of welded joints depends on an assessment of the various features of the welded joint. The minimum weld geometry is in part based on the quality assessments contained in (![]() NASA-STD-5006, 1999).

NASA-STD-5006, 1999).

12.5.4.1. Estimation of the Weld Throat thickness, a

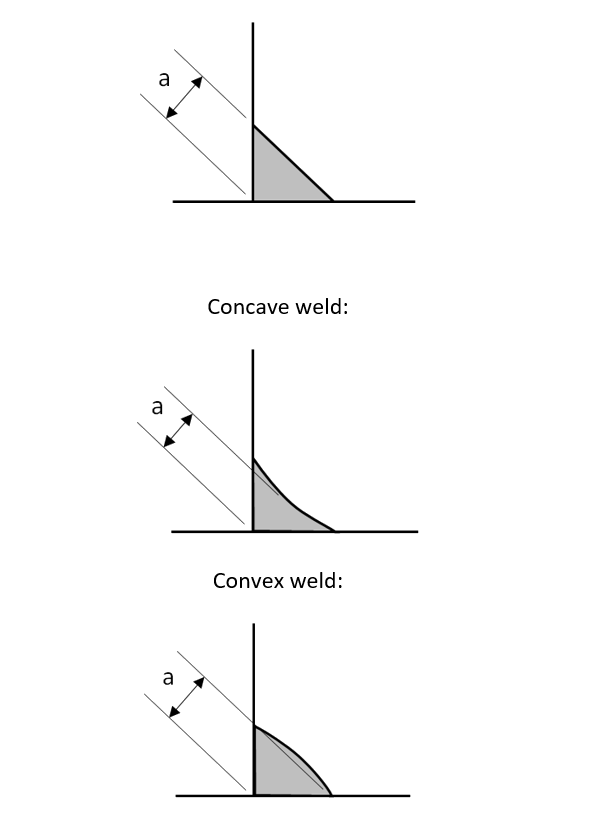

The weld throat thickness is the effective thickness that should be used to calculate the geometric properties to calculate section stresses.

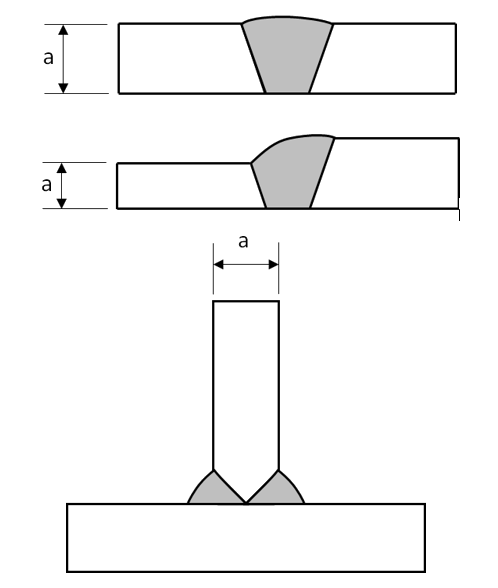

For full penetration welds:

Partial Penetration welds:

Note that for primary structure the weld must always be full penetration. Partial penetration welds are suitable for secondary structure only.

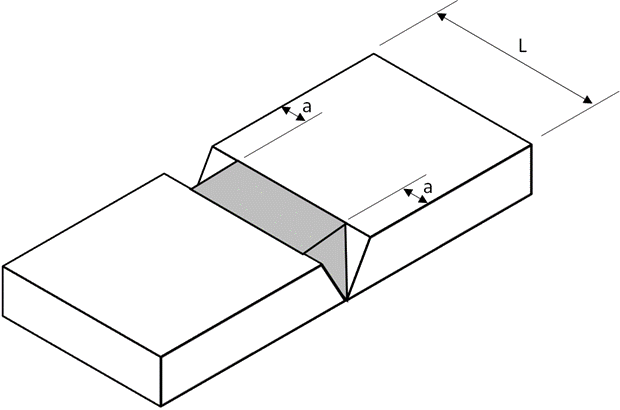

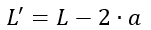

12.5.4.2. Estimation of the Effective Weld Length, L’

It is conservative to assume that a length equal to the throat thickness is missing from each end of the weld. Therefore, the effective weld length:

Other Useful References for Welding:

![]() NASA-MSFC-SPEC-3679 Process Specification – Welding Aerospace Hardware

NASA-MSFC-SPEC-3679 Process Specification – Welding Aerospace Hardware

Complete List of Welding references at the Abbott Aerospace Technical Library: