(![]() NACA-TN-3781, 1957) is the best available reference (again) and gives a simple rational method for how to account for the presence of cladding.

NACA-TN-3781, 1957) is the best available reference (again) and gives a simple rational method for how to account for the presence of cladding.

NACA-TN-3781, 1957)

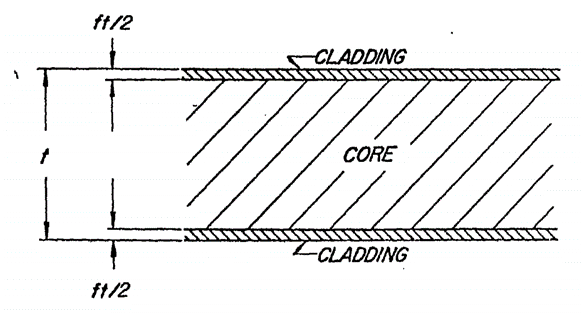

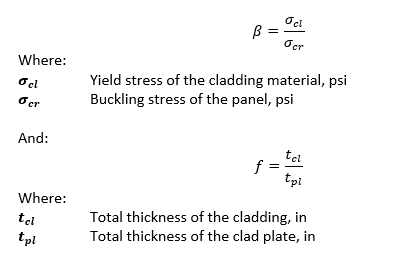

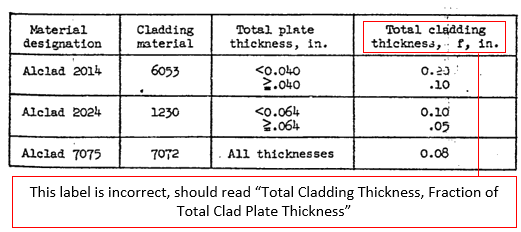

NACA-TN-3781, 1957) The reducing in buckling due to the presence of cladding depends on two ratios:

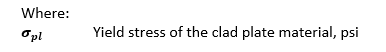

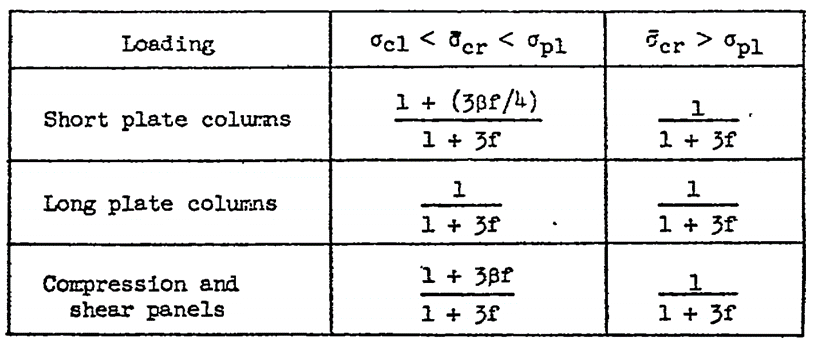

For different loading conditions and stress level the following terms apply.

NACA-TN-3781, 1957)

NACA-TN-3781, 1957)

NACA-TN-3781, 1957)

NACA-TN-3781, 1957) This method is available in this spreadsheet:

Note that in some circumstances, particularly for panels with low buckling allowables, a cladding reduction factor of greater than 1.00 can occur. In this circumstance a maximum value of 1.00 should be used.