Earlier posts here and here,

Prompted by my colleagues in the industry I posted my comments to the FAA – the text of my submission is duplicated below and there is a link to the pdf document of the same at the end. After further consideration I have come to the conclusion that the change to the Part 23 regulations is a bad idea. I would love to hear your opinion on this.

May 10 2016

Docket Operations, M-30

US Department of Transportation

1200 New Jersey Avenue SE

Room W12-140, West Building Ground Floor

Washington, DC 20590-0001

Docket No.: FAA-2015-1621

Docket Name: Part 23 Reorganization

RE: Comments on the proposed change to the Part 23 regulations: The impact on aircraft developers and their supply chain and the legality of the change

Mr. Lowell Foster and the FAA,

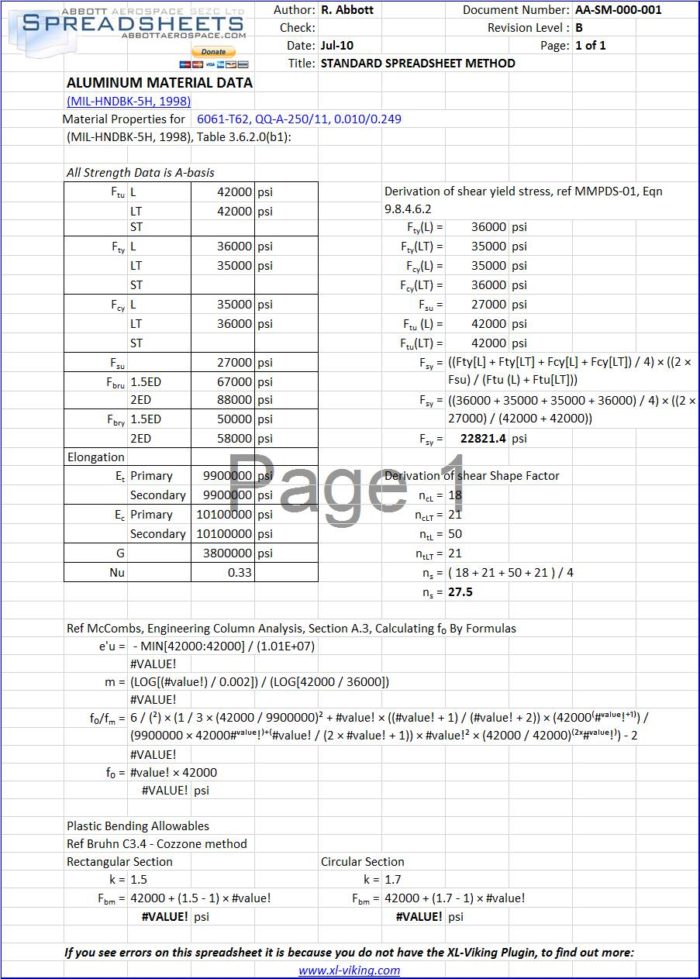

Abbott Aerospace SEZC Ltd is not a US Corporation and none of our directors or employees are US citizens. We are based in Grand Cayman with a project office in Canada. We are currently engaged in significant airframe and system development work for four part 23 US based new aircraft development programs and advise and carry out engineering and compliance work for many other US based civil aerospace organizations. I hold structures and mechanical systems signatory authority on two of the aircraft development programs we are engaged on.

Our vested interest in this discussion is the health of the US part 23 aircraft development sector. Any additional cost that the proposed change to the part 23 regulation imposes on the industry that is not offset by cost reduction elsewhere does harm to the industry.

Seventy-five percent (75%) of our business is with US start-up companies. Our experience demonstrates that the high business failure rate among aerospace start-up companies is due to financial reasons, and not for technical reasons. If the proposed changes to the regulations have any significant negative financial impact to the industry, this has the potential to increase the failure rate of emerging US aircraft companies. Compliance cost is a large component of overall aircraft development cost.

The Change to the Regulations and Effect on the Industry

It is noted that regulations are not law, regulations are rules that govern how laws will be enforced. However, regulations often have the same force and effect as laws. For the most part the federal aviation regulations have the same effect as law with allowed exceptions, (Equivalent levels of safety, etc)

The proposed regulations have almost all specific requirements removed, the current regulations are being repurposed as advisory material and exclusively licensed to ASTM

“A standards organization such as ASTM could, for example, generate a series of consensus-based standards for review, acceptance, and public notice of acceptance by the FAA. The ASTM standards would be one way, but not the only way, to demonstrate compliance with part 23.”

In the proposal, the existing set of regulations with approved modifications, through licensing to ASTM, will become an acceptable means of compliance.

The ASTM draft standards define, or purport to be, a new comprehensive set of optional regulatory standards. If the intent is that the ASTM standards are to be advisory only it is recommended that ASTM do not duplicate the entire body of regulations (with some FAA approved changes) and that the ASTM standards should read as if they are advisory material per the existing Advisory Circular system.

Under the proposed system do the existing set of part 23 regulations (unchanged) become an acceptable means of compliance? I.e. can aircraft developers just reference the current set of part 23 regulations, even though they are superseded, as these are very similar to the wording of the proposed ASTM standards?

Does the government have the power to take existing regulations (law) and make them advisory only without changing the language in a substantive manner?

If the federal regulations are in effect mandatory (law) and the proposed ASTM standards are advisory (not law) why do the proposed ASTM standards duplicate the wording and structure of the current law and employ imperative terms such as “must”, “shall”? If the ASTM standards are advisory only, why do the ASTM standards not follow the content, structure, wording or intent of the existing advisory material with additional material taken from the current set of regulations where necessary. This misrepresentation will lead to confusion and people and organizations will incur the cost of purchasing the ASTM thinking that they constitute law and that compliance to the ASTM standards is mandatory.

The proposed change is akin to making the following change to the law regarding speed limits

- The government changes the regulation to read “The Driver must drive at a safe speed”

- The government changes the numerical speed limit levels to advisory status, makes minor changes to the advised speed levels, licences this information to an ‘organization’, makes them proprietary IP of the ‘organization’ and allows the organization put them behind a paywall.

- The advisory material, now owned by the ‘organization’, maintains the imperative language of the previous law. The advisory material reads “Under any circumstance the driver must not exceed 52mph”

- Each person using the road could then pay a fee to the ‘organization’ to discover the advisory speed limit or they could submit an individual speed limit proposal along with appropriate justifications that would be reviewed at the convenience of the government and the driver would then bear the cost of the submission, justification and delay.

The comparison can be extended

- The driver may be able to reference the obsolete version of the law when making a submission for his/her safe speed. The submission may be rejected for reasons unknown.

- The driver is not allowed to see the current acceptable speed limit (the speed limit that is now acceptable to the government) without paying the ‘organization’.

- Over time the acceptable speed limit will change and deviate from what was specified in the old law. In order to see the new speed that the government finds acceptable the driver has to pay the ‘organization’.

- The ‘organization’ is allowed to change and revise the acceptable speed limit on a regular basis. Drivers who choose to show compliance by paying the ‘organization’ find they have to pay the ‘organization’ on a regular basis to make sure that the changes do not affect the speed limit that they have elected to use.

- If a driver, who has paid the ‘organization’ to find out what the acceptable speed limit is, shares that information with a driver who has not paid the ‘organization’ that driver can be subject to court action and punitive measures.

Under this equivalent situation the driver sees an increase in cost no matter what option they take. Clearly this type of change to the structure of the speed limit law is absurd to consider in this context. How less absurd is this change in the context of the rules regarding aircraft safety?

How will Industry regard and use the proposed ASTM standards?

To propose a change in the wording of the existing regulation, re-purposed as advisory material and making them private intellectual property of a non governmental organization while simultaneously allowing a consideration of any alternative approach will result in two likely outcomes.

- The Industry will understand that the least risk route through the certification process is to follow the new ASTM standards (essentially what used to be the old law) and almost everybody will follow that approach. This will keep the FAA staff in their comfort zone, allowing them to make findings of compliance in a timely manner based on metrics and standards they are familiar with, or

- A rejection of the new standards resulting in a ‘wild west’ of multiple proposed compliance methods and proposed individual project based standards. FAA staff will be overwhelmed giving all of these compliance methods due consideration and the certification process for the industry grinds to a halt.

Clearly 2) is almost certain not to happen as all companies and engineers will realize the consequences of taking this approach and follow option 1).

Option 1) is a route that will result in guaranteed additional costs to the industry. Those are the costs of purchasing the ASTM standards and the general delay and confusion associated with any change. Option 2) is the route that will paralyze the certification process as the FAA will be overwhelmed reviewing multiple re-interpretations of what used to be law.

The unavoidable additional costs imposed on the industry from option 1) result in additional revenue for one organization, ASTM. There is no benefit from the proposed change that a rational update to the part 23 regulations could not have provided. The option of an OEM creating and proposing their own standards is almost certain not to be used other than for individual ‘controversial’ cert issues and in any case these issues will be regarded and treated in the same manner as issue papers are under the current regulations. (see later note: ‘A report from the 14CFR Part 23 Reorganization Aviation Rulemaking Committee to the Federal Administration Aviation’ June 5, 2013)

In effect the proposed change only guarantees one outcome – Additional cost placed on aircraft developers and that cost translating into revenue for the ASTM.

Are the proposed ASTM standards regulations?

The proposed ASTM standards contain the bulk of the current regulations; the proposed regulations have had many or all specific requirements removed that will now exist in the ASTM standards.

The ASTM standards have been created and complied with the permission and assistance of the US Federal government and coincide with, and coordinate with, a significant update to the federal regulations and consist of the previous revision of the regulations.

The ASTM standards contain multiple occurrences of imperative language (“Shall”, “Must”, etc)

The nature of the ASTM standards means that while they are called ‘advisory’ they will be the favoured ‘advisory’ materials (consisting largely of the previous federal regulations) and departure from the favored advisory materials will incur significant and potentially prohibitive additional direct compliance cost and delay and the overall program cost associated with the delay. Ref ‘A report from the 14CFR Part 23 Reorganization Aviation Rulemaking Committee to the Federal Administration Aviation’ June 5, 2013 (https://www.faa.gov/about/office_org/headquarters_offices/avs/offices/ air/directorates_field/small_airplanes/media/P23_Reorg_ARCFINAL.pdf), this document acknowledges the cost and time to develop alternative consensus standards

“The ADS are not limited to ASTM International standards and there is no limit on how many consensus standards could be accepted. Other consensus standards developed by other organizations or individuals would follow the applicable processes necessary to satisfy the FAA or other regulatory agency requirements for consensus standards. Other consensus standards may be required to follow the FAA Issue Paper process that can take a significant amount of time to develop and approve. This process might be used when a company wishes to use a standard as a means of compliance but to retain it as proprietary information.”

Development of competing consensus standards:

It is very unlikely that other consensus standards will be developed in the foreseeable future considering the expense and time involved. It is very likely that the ASTM standards will remain the only set of standards acceptable to the FAA that can be used for a significant and indefinite amount of time. This fact is acknowledged in the referenced report.

This report effectively acknowledges that ASTM have in effect been given an unfair advantage by the FAA as the ASTM have developed their standards with the cooperation of the FAA incorporating the latest changes to the existing regulations envisioned by the FAA. ASTM has been given ownership over the proposed updated version of the current regulations, repurposed as ASTM standards. These proposed ASTM standards may not be used as a starting point for any other ‘consensus organization’ to develop their own competing standards as they are now owned by ASTM.

The ASTM standards are the only consensus standards available.

Does a practical alternative to the ASTM standards exist?

The motivation to rely on the ASTM standards will be difficult to overcome for most companies and deviation from those standards will likely only occur if the aircraft product is unique and not covered by the ASTM standards. In which case the aircraft developer would still have to purchase the standards to find that they are not applicable.

The outcome of this proposed change is that all aircraft OEMs and much of their supply chain will be put in a position where to find out if the ASTM standards are applicable and useful they will have to purchase them. If those companies are engaged in aircraft development over the long term they will also have to purchase all of the updates and revisions over time – just to find out if they are useful.

If alternative consensus standards are eventually developed by another standards organization, aircraft OEMs and their supply chain will be put in the position or purchasing two sets of standards to discover which best applies to their aircraft product.

The referenced report also implies that companies wishing to submit different, new or unique means of compliance to the FAA under the new regulations, and keep them proprietary, (the same privilege granted to ASTM) the FAA issue paper process should be followed and “that can take a significant amount of time to develop and approve”.

Aircraft developers and their supply chain will, in effect, be forced to purchase the ASTM standards and use them or they will face additional significant cost penalties and schedule delay. Because of the way the FAA have cooperated with only the ASTM in developing standards at this stage, the time it takes to develop new standards and because the latest and updated acceptable means of compliance are now proprietary to the ASTM it is not certain that any competing standards will ever be developed and if they are it will take a significant amount of time for them to be made available.

My conclusion is that the new ASTM standards will become de-facto regulations because of:

- The specific technical content of the standards and how they are comprised of almost all of the previous revision of the federal regulations.

- The way the standards have been created with the cooperation, input and approval of the federal government

- The way that the ASTM standards also include updates and improvements to the current set of regulations developed with the assistance and cooperation of the FAA

- The language of the regulations has not been significantly modified by ASTM and have multiple uses of imperative words indicating that the standards are not advisory in nature and are mandatory

- The way the standards will be likely used and interpreted by the industry

- The significant financial and time penalty for choosing not to use the ASTM standards effectively makes use of the standards the only viable option for all aircraft developers.

To quote from https://www.publicknowledge.org/press-release/ concerning a case between ASTM and Public.Resource.Org

Free and unfettered access to the law has long been a cornerstone of American democracy. Plaintiffs’ claims are a blatant attempt to use copyright law as a bulldozer against the public domain. Their claim that incorporated statutory language is eligible for copyright protection because it is ‘creative’ (and can thus be ‘paraphrased’) ignores the fact that the words of the law are definitive; rephrasing the law is no substitute. More importantly, the public’s access to the exact text of the law is a fundamental right drawn from the Constitution.

There are several legal precedents where privately developed codes of practice have been incorporated into regulations and codes and subsequently been found to be non copyright protected because of their adoption by state or federal agencies:

Veesk v. Southen Building Code Congress Int’l https://en.wikipedia.org/wiki/Veeck_v._Southern_Building_Code_Congress_Int%27l

Public.Resource.Org vs SMACNA https://www.eff.org/press/releases/publicresourceorg-prevails-free-speech-case-over-publishing-safety-standards

To take an already existing law or regulation and turn it over to a private standards organization, allow the organization to work with the government department to update and improve the law and allow the agency to claim ownership and charge for access to this information when no alternative, credible or otherwise, exists is not allowed under US law.

Conclusion

The proposed revision to the part 23 regulations;

- will, at best, Impose a new, unavoidable and unnecessary cost on aircraft developers and their supply chain

- provide ASTM with an effective monopoly and a new guaranteed revenue stream.

- Is illegal as the new standards constitute de-facto law despite being labelled ‘advisory’ are the only realistic path to certify an aircraft.

I appreciate the intent of proposed change to the regulations, but I find that the outcome of the change will not achieve the intended result and will have an overall negative impact on the industry. It is my opinion that the proposed change is illegal.

There is no clear indication how the proposed change would reduce net cost or expedite the certification process. There are clear additional direct and potential significant additional indirect costs created by the proposal, but there is no obvious or defined cost reduction associated with the proposal.

We recommend that because the ASTM standards are de-facto law and they represent latest and best thinking on aircraft safety that they must be kept in the public domain. This is the only course of action that is likely not to result in additional increased costs for aircraft developers and their supply chain and will provide the highest safety level for the industry. Note; the cost impact of the change to the content of the regulations, now the proposed ASTM standards, is unknown and may represent another, as yet, unassessed and unavoidable cost for aircraft developers and their supply chain.

Sincerely.

Richard Abbott

President, Abbott Aerospace SEZC Ltd

www.abbottaerospace.com

Pdf version here: AA-FAA-2016-001

To try our free Stress Analysis Engineering Spreadsheets click below

To try our Add-in for Microsoft Excel for Windows click below

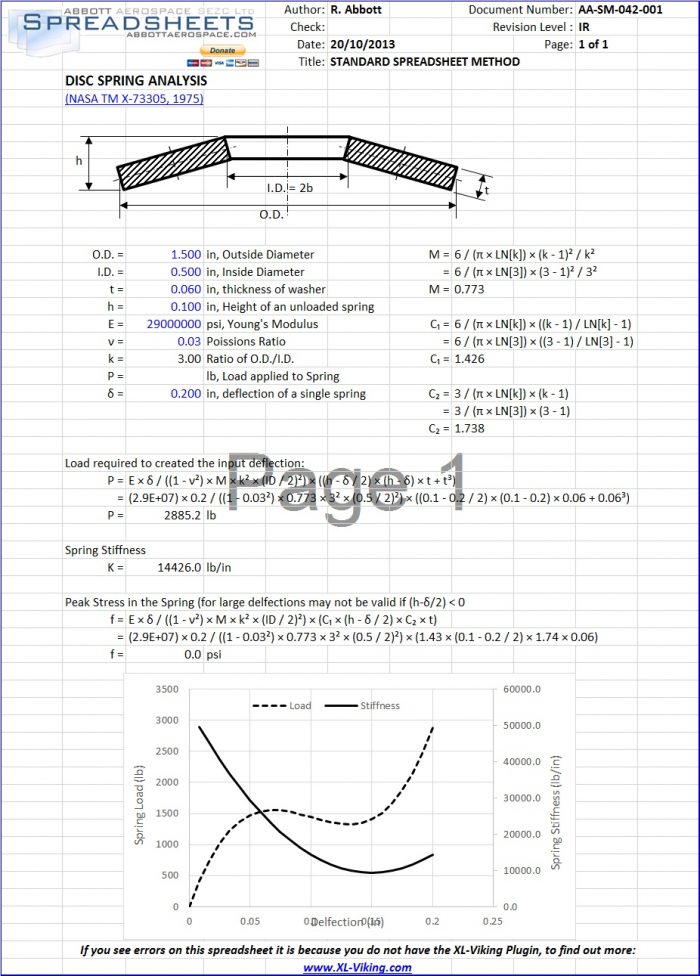

We had to design a set of belleville washers for a client last year so we had to go and find a useful design criteria. NASA came to the rescue this time. In (NASA TM X-73305, 1975) there is a simple method for sizing and behaviour of disc springs.

We had to design a set of belleville washers for a client last year so we had to go and find a useful design criteria. NASA came to the rescue this time. In (NASA TM X-73305, 1975) there is a simple method for sizing and behaviour of disc springs.

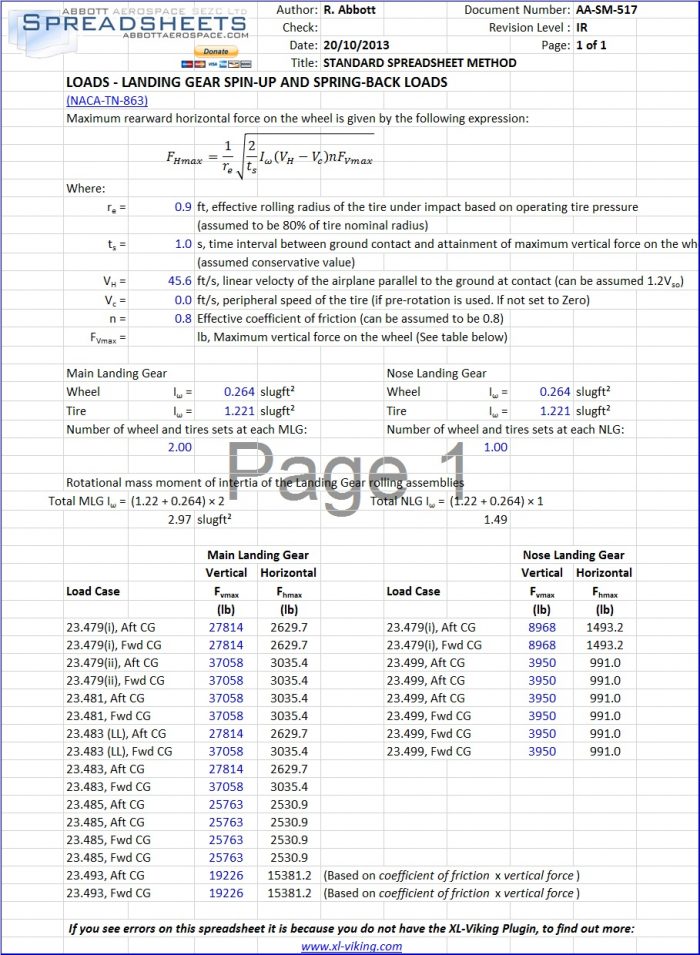

There is a relatively simple method in the FAR part 23 appendix for calculating rational landing gear spin-up and spring-back loads. This method is referenced to and better explained in

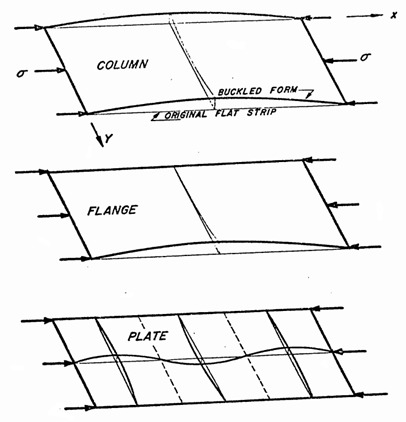

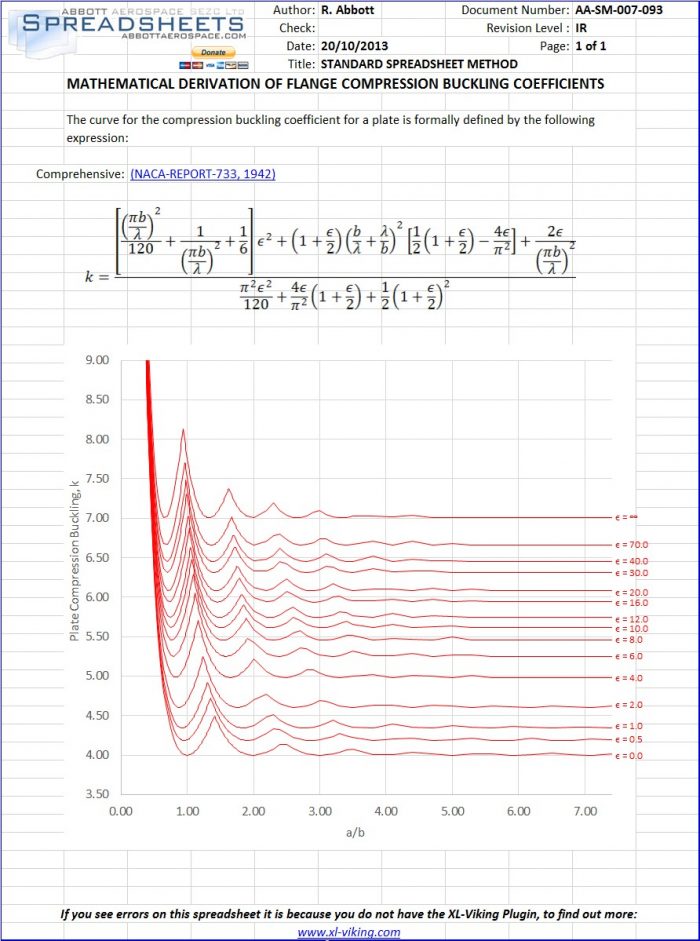

There is a relatively simple method in the FAR part 23 appendix for calculating rational landing gear spin-up and spring-back loads. This method is referenced to and better explained in  We have been working had to complete the buckling methods for the first official release of the text book. Because of the scope and depth in which we want to cover the subject we are going to limit the scope for the initial release of the book to initial buckling of flat panels, including looking at panel breaking stiffeners and the effect of circular holes.

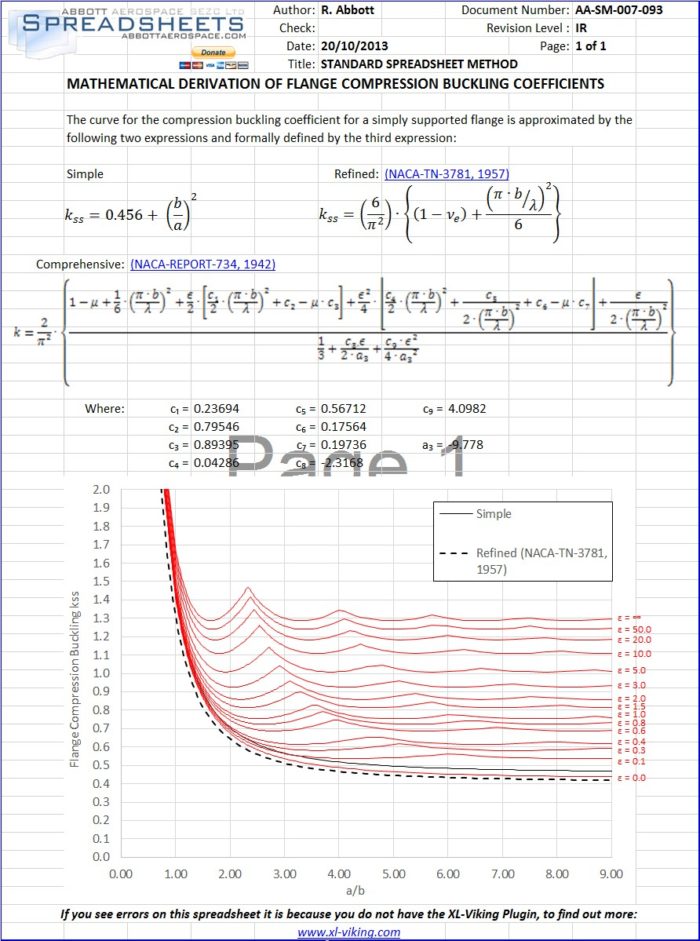

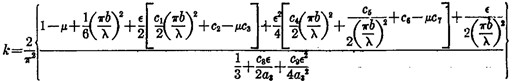

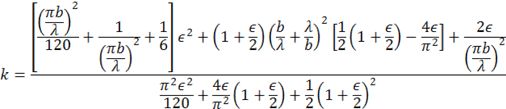

We have been working had to complete the buckling methods for the first official release of the text book. Because of the scope and depth in which we want to cover the subject we are going to limit the scope for the initial release of the book to initial buckling of flat panels, including looking at panel breaking stiffeners and the effect of circular holes. Again, NACA provides a the solution to another problem. The theoretical derivation of plate compression buckling coefficients. I had a simple derivation, which uses this equation for the simply supported plate buckling coefficient

Again, NACA provides a the solution to another problem. The theoretical derivation of plate compression buckling coefficients. I had a simple derivation, which uses this equation for the simply supported plate buckling coefficient

deleted the old one and created a new one from scratch. We went through the verification for our new Google+ page for our new location and map entry and all was good. Google then automatically created a Google+ page and a map entry for the defunct business in Canada and I had to go through the process of shutting that page down – twice.

deleted the old one and created a new one from scratch. We went through the verification for our new Google+ page for our new location and map entry and all was good. Google then automatically created a Google+ page and a map entry for the defunct business in Canada and I had to go through the process of shutting that page down – twice.