Towards the end of 2021 I connected with Eugene Pik on Linkedin. Eugene is an interesting guy – raised in Soviet Belarus, moved to Israel and has been running his business in Canada for many years.

He wanted to produce a eVTOL aircraft that would serve the medical evacuation (medevac) market better than the helicopters that are currently being used.

We had some long discussions and we made a few decisions. We would seek to make the project and the corporation fully open source. This decision is where the articles on open source have come from and this has proved to be very interesting.

In the name of open source we would be honest about all aspects of the program. We would make no optimistic projections, we would seek to exploit no markets that do not currently exist, we would not plan to set up our own operations company to place orders for the product.

We would set up the commercial aspect of the program like any other traditional aircraft program and see if it could work.

So we started as all aircraft programs should. We talked to the customers and users. Eugene lined up conversations with many medevac operators in Canada and the US and we listened to everything they had to say.

We learned that the Canadian and US business and operating models are quite different. The US market is served by operator subcontractors where the operating cost is a very significant part of their operation. The Canadian operations are vertically integrated where the flight operations are just part of a larger organization and the vehicle operating costs are not driving the choice of vehicles.

We learned that noise is a big issue as operators flying into city hospitals get multiple noise complaints for every flight they make and they need to carry the pilot (sometimes 2 pilots), two medics and two patients (in some states).

In the US the flight durations are low and operators in both countries have problems getting into some landing areas because of the space needed for the main and tail rotors and the hazards they represent to potential bystanders.

We also learned that helicopter floors are not designed to be fluid proof and there are significant problems with cleaning and sterilizing the helicopter and the underfloor areas.

The vehicle would need to be capable of IFR operations and would need large double doors at the rear to allow easy loading and unloading of patients, and especially larger patients.

In a relatively short time we had a good picture of the market requirements and set about configuring the vehicle.

The Vehicle

Batteries

If you have read this newsletter before you know the physics based approach I use for battery based feasibility studies so we discounted batteries after the first high level assessment. There is no battery powered hovering vehicle that can meet IFR reserve requirements and have any useful load or range left over – if you consider the currently available energy densities.

Hybrid

If you want to use electric motors to avoid direct (or indirect) drive from a piston or turbine motor then you have to use either hydrogen fuel cell or on board electrical generation based on hydrocarbon fuel.

As I have noted before Hydrogen has great energy density and lousy density – unless you keep it close to zero Kelvin. As well as the impracticality of onboard hydrogen storage there is also no production and delivery infrastructure for hydrogen and there is no type certification path for hydrogen fuel cell systems.

With all of this in mind, and keeping ourselves based in reality you end up with a turbine generation system. There are certified turbo generation systems (these are called APUs) but these systems are not very high efficiency but they do exist. We would have to plan to develop our own or partner with a supplier to develop a system. However it would be physically possible to create a generator and there is a preliminary path through the certification process for a turbo generator.

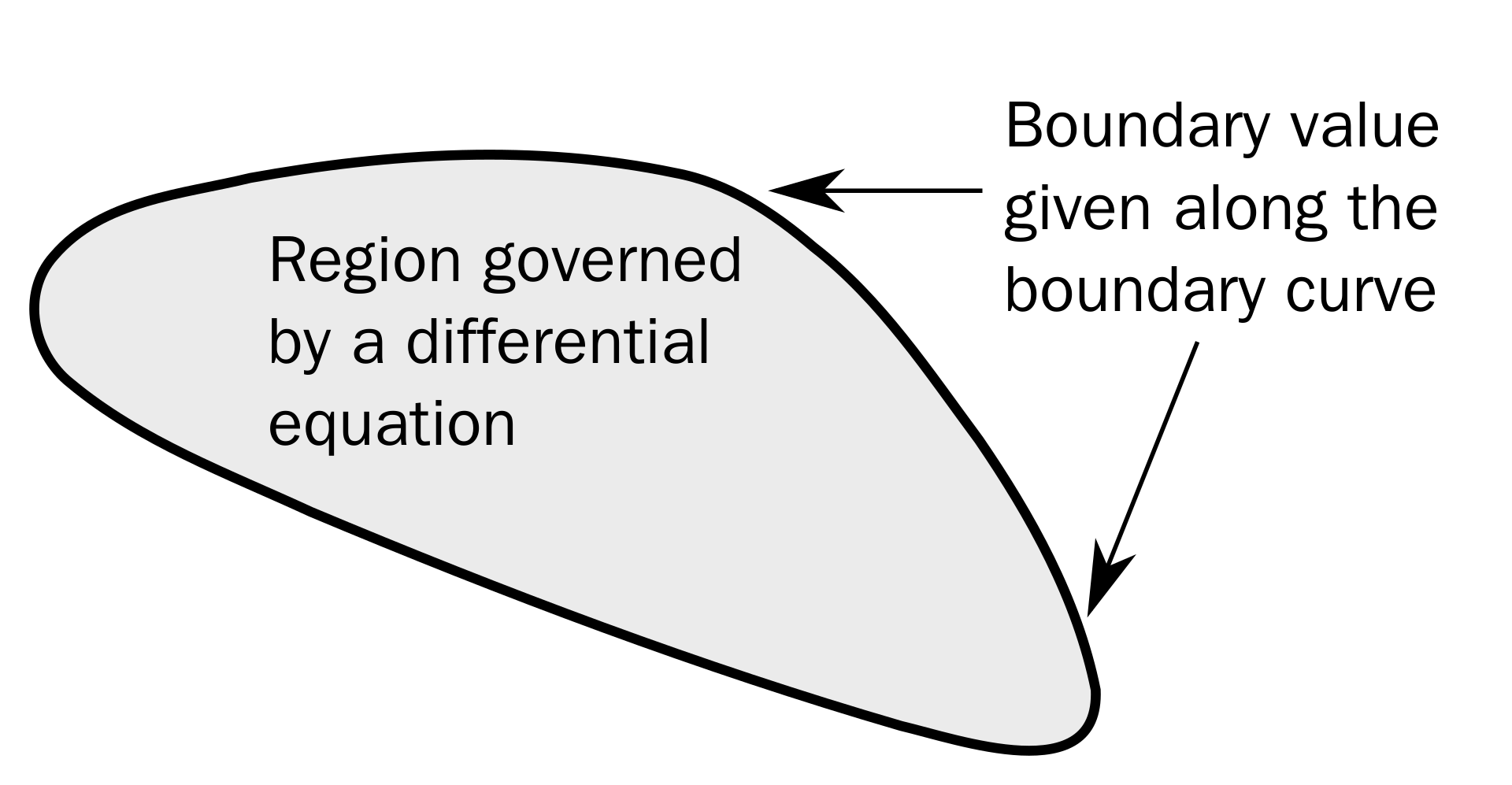

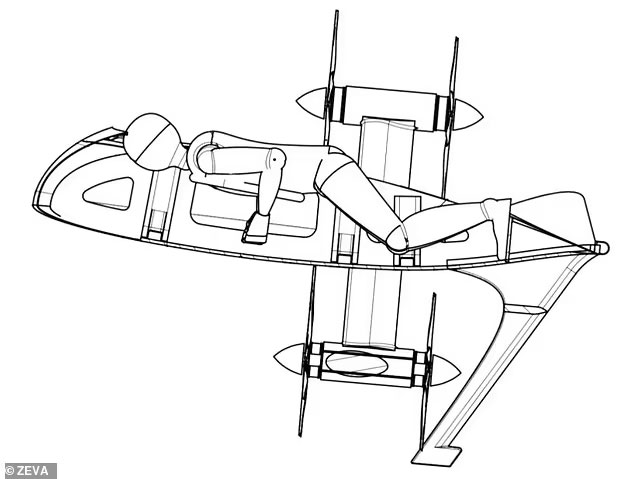

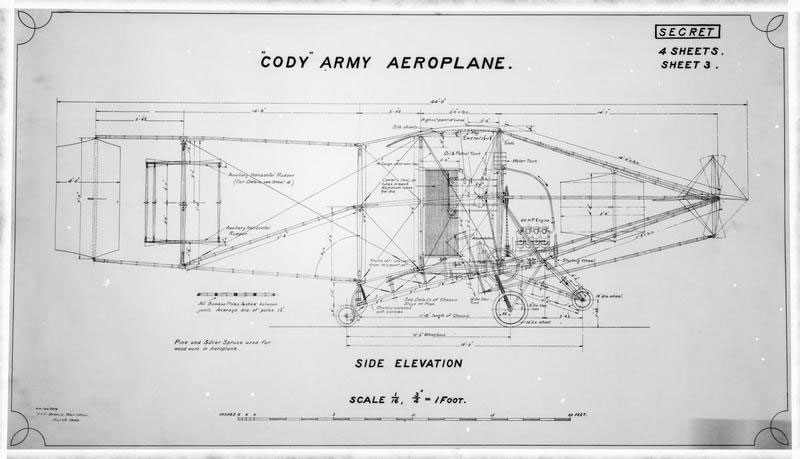

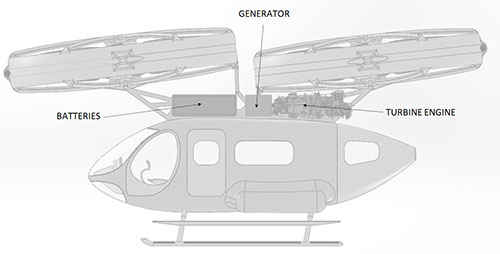

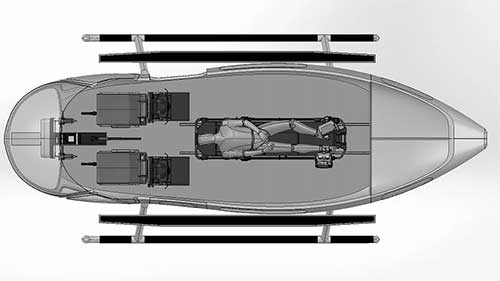

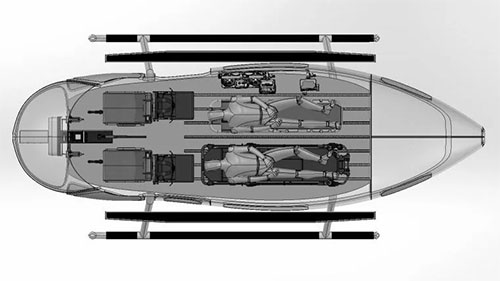

This is a view of a preliminary loft of the aircraft with turbine engine, generation and buffer/emergency power battery packs

How is it going to fly?

Well – wings and conventional landing are out of the question so it would have to be a rotorcraft of some type. It would have to have a smaller overall footprint than a traditional helicopter. Smaller rotors mean lower disk area and reduced hovering efficiency. Hybrids already have an efficiency loss compared to direct drive systems so we need to have the rotor disk area as large as possible.

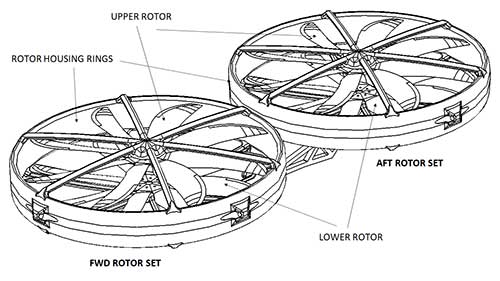

In the end we settled on two pairs of stacked counter rotating rotors. These would have to be relatively closely coupled. This would allow us to create an effective larger rotor area for the same footprint and help drive up efficiency.

In addition, if we house these twin rotors inside a ring we may get some duct efficiency, it would help protect people from the hazard of the rotors and help mitigate noise problems.

If we selected a twin turbo generator system we could split the power from the two turbo generators so one generator drives one rotor in each of the pairs. This way if we suffered an engine loss we could still retain control as a single fan in each of the two sets would remain operable for safe flight and landing.

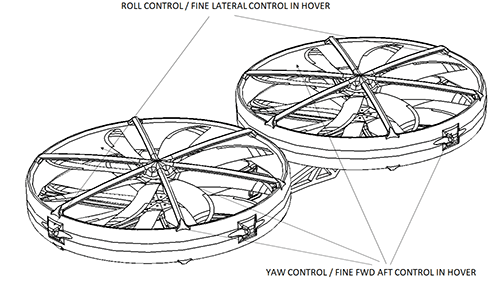

Flight Controls

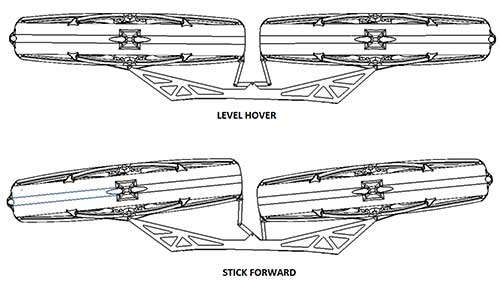

Pitch control (or for/aft control) will be achieved through a direct mechanical connection to the rotors themselves:

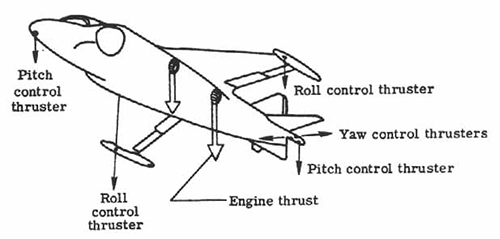

Other axis controls will be achieved through the use for reaction control valves similar to the RN Sea Harrier or Harrier AV8B:

A nice side effect of using turbine engines is that you have bleed air that you can tap into to drive the reaction control thrusters and also to heat the cabin. Cabin heating is a problem that battery control and fuel cell powered aircraft have yet to address.

Software control will be avoided in favor of direct mechanical connection to the reaction control valves. This has yet to be detailed and we may find that some software management of the flight control system is unavoidable

The Fuselage

In this layout of the interiors much credit must be given to Ferno. They went above and beyond being a mere potential supplier and helped us lay out the interior for multiple configurations. They made sure we gave enough space to carry the medics, the patients and the equipment and allow the medics to work around the patients in flight.

We also have to acknowledge the help of Norman Wijker in lofting the fuselage and the fairings above the cabin. Norman went above and beyond in producing a body and fairing shape that met our needs and then some.

The Final Preliminary Configuration

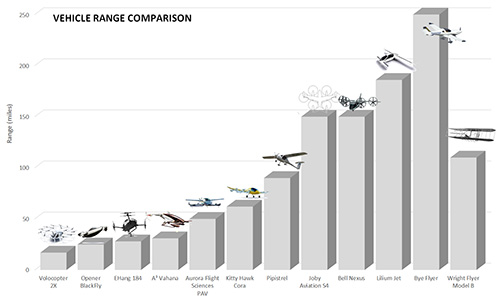

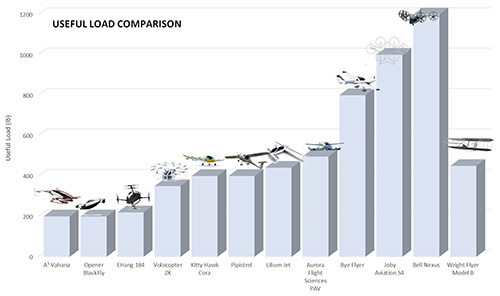

Having identified a market segment, we talked to the customers, defined a specification, reviewed the available technology and the competition and sketched out a preliminary configuration:

90 minute flight mission with 30 minute reserve for 1 or 2 pilots, two medics, and 1 or 2 patients

- Flight time: 90 minutes + 30 min reserve

- Speed: 125 knots (232 Km/h, 144 Mph)

- Useful weight (payload): 1530 lb

- Weight of the medical equipment: 500 lb

- Total weight: 7000 lb

- Number of medics: 2

- Number of pilots: 1 or 2

- Number of patients: 1 or 2, up to 400 lb total

The resulting vehicle would be a part 27 twin engined turbine powered rotorcraft specifically designed to meet the mission based requirement in a medevac role.

There are some technical risks that we need to address:

Certified turbo generation system, close twinned counter rotating rotors, flight control system avoiding software, power plant failure modes.

However, there are not many risks that thoroughly violate established physical laws – that puts us in pretty good shape for an eVTOL program.

The Business

The essence of the business case is that you have to be able to generate enough revenue and profit to justify the investment and the timeline to revenue and profit.

Aircraft programs required a lot of money and a lot of time to get to profit.

Profit is a function of the economy of scale you are working at. The fewer vehicles you produce the greater the cost per unit you produce and lower the profit. If you can’t produce and sell enough units you cannot get the cost down low enough to make a profit and you operate at a loss (or ‘negative profit’ for the diplomatically minded).

If you start a company and you only have one product you need to sell enough of the profit to support all of your company facilities and systems.

If you examine the helicopter industry no successful company just produces one model of helicopter. I.e. they create leverage from their company facilities and systems to generate acceptable economies of scale because the sales from a single class of helicopter is not sufficient to create acceptable economies of scale.

In short: You need to sell a bunch of vehicles or you’re gonna get in trouble.

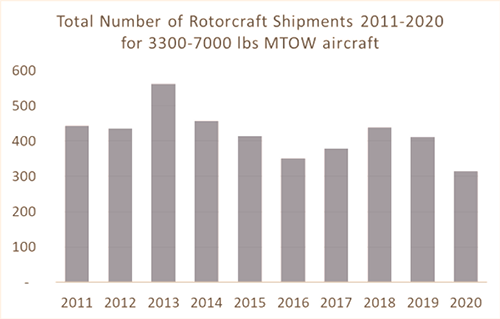

How many vehicles can you really expect to sell? Eugene investigated the business case and the first port of call is the GAMA production numbers. This is a sobering read.

In a good year the global sales in this segment reaches 500 units:

The number sold is more realistically in the 300-400 unit range. – so let’s use 350 units per year as the global market for new vehicles.

If we achieve 10% global market penetration (35 units a year) would we be profitable? From my experience and preliminary numbers the answer is ‘barely’. So realistically the answer is that we would have to achieve at least 10% market penetration just to break even.

We will be competing with Bell, Airbus and Leonardo (Agustawestland). Would they be able to aggressively price their products and rely on their MRO revenue to sustain them in order to get the orders we would need to survive. Answer: Yes.

Would we survive? – a barely profitable company with minimal to no MRO revenue having to discount our products just to get into the market. Answer – Almost certainly No.

So Eugene (along with Taras Lyssenko – long time associate and trusted voice of reason) decided to post the project as an on line ‘white paper’ on commercial viability

The Hype

So how do you make the business case for a startup company developing a single vertical take off air vehicle?

- You need to create a business case with compelling revenue and profit.

- This means you have to produce more aircraft in your class that are currently sold globally

- In turn you need to present a market that does not currently exist that supports the sale of thousands of new aircraft every year.

- That market is based on a price point that can only be justified by the low cost of the vehicle based on the size of the market which is based on a price point that can only be justified by the low cost of the vehicle based on the……..

You end up in the circular logic of the chicken and egg where neither the chicken or the egg have yet to be shown to exist.