A version of this article first appeared in the April 2019 edition of our free newsletter, to subscribe click here

This is not a comment on the progressive political ideology, although it may be tangentially relevant. It is a comment on human nature and is prevalent on every aircraft development program as well as in the political sphere.

Humans have a great desire to fix stuff. Most intelligent animals do – from beavers to the bees and the birds. The desire to build is a desire to fix.

We try to create order out of chaos. We take things without form, or with chaotic form, and we order them and give them purpose. We change them. We improve them. We fix them. We call this progress.

Throughout human history the result of this instinct has created a net positive. All but the most ardent environmentalists acknowledge the overall benefits of the industrial revolution. Modern medicine, computers, flight and even the less obvious things like affordable clothing, effective detergents and soft toilet paper.

There are two obvious negative behavioural aspects that this instinct creates. These are the desire to fix something that isn’t broken, and, the desire to perfect something that is already as good as it can be.

This article passed across my screen one morning (https://www.forbes.com/sites/marisagarcia/2019/03/29/why-fixing-the-faa-designee-program-is-not-a-matter-of-money/) courtesy of my linked-in feed.

This is a typical human response that derives from the desire to perfect something that is already as good as it can be.

The FAA delegate system is wildly successful as it allows a reactive, cost effective and high quality compliance environment.

The current system does not tie aircraft developers, big and small, into an intimate and invasive partnership directly with a large government bureaucracy. While this can work, it is impossible for the FAA to have full time staff who are familiar with all aspects of every type of aircraft, material combinations, manufacturing processes, etc.

The current system allows for a pool of independent and licensed experts working on behalf of the FAA with a breadth of experience and knowledge that is unmatched.

The current system also provides two levels of justification and advocacy. What usually happens is that the company engineers have to present and justify their approach to the delegate. The delegate then often goes through the same process on behalf of the company with the FAA to get the FAA’s buy-in to the desired compliance approach.

On the face of it, this may sound more inefficient than a single stage process. There are several reasons why this actually has a beneficial effect:

- The company has two levels of review within the compliance function. One from the delegate and secondly from the FAA.

- The FAA, because of the move towards frontline staff with greater academic credentials rather than experience, has become more literal and inflexible in the interpretation of the regulations. Experienced delegates are often required to advocate on behalf of OEMs means of compliance that are not financially ruinous.

It is the current US system that has created an environment that has fostered the most successful private aviation industry in the world.

It is not perfect.

But…..it is very important to separate a failure of the application of the system from a dysfunctional system.

If you have a dripping tap (or faucet) you don’t disconnect the mains water, dig a well and contract a plumber to install a pump and filtration system, rip out all of the water pipes throughout your house and replace from new.

You replace the washer.

To use the 737 MAX problem as a way to start a discussion centered around how to fundamentally change the way a finding of compliance is made is very ill advised.

It is not that the current system cannot be improved, but as all product development engineers know, successful product improvement is brought about by careful iterative change.

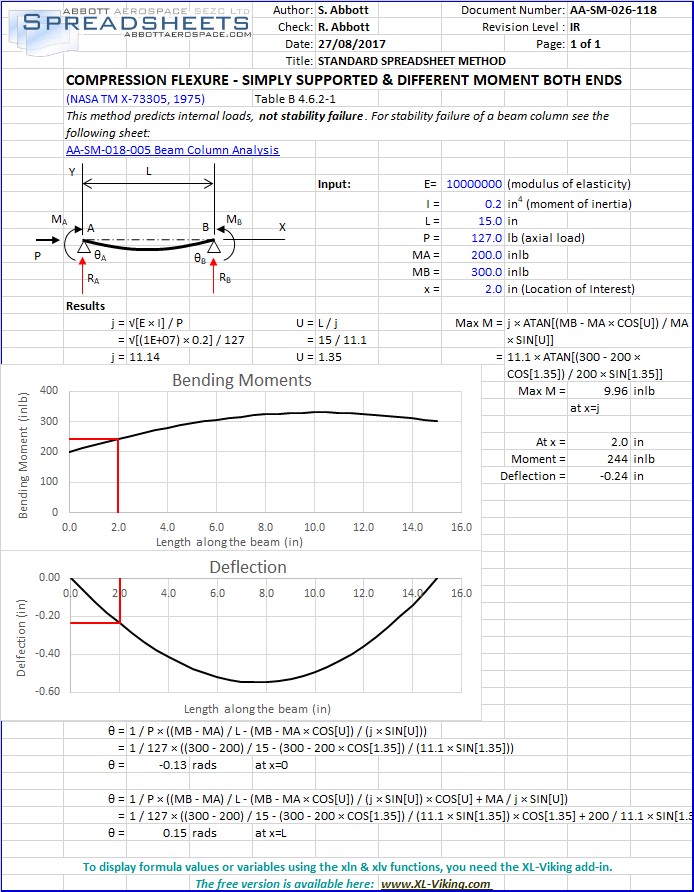

Boeing of all people know this – after the consideration of the Boeing 2707 and the Sonic Cruiser and their subsequent cancellations they understand this. 43 years of iterative commercial aircraft design is shown below:

The Boeing 737-200 (1968)

Boeing 787-800 (2011)

The Forbes article does get it right.

“What has made the Designee program strong over the decades has been the stringent requirements to qualify, a focus on safety as an industry priority, and the civil and criminal penalties for those who breach their commitment to oversight.”

To change the system to a centralized body would be a shift away from the American philosophy of personal responsibility towards a more European model of direct federal oversight.

When was the last time any civilian government worker was held civilly or criminally liable for incompetence? I am not saying that people who work for the government are not hardworking or diligent. However, in an environment where the last .01% of careful consideration matters I prefer to trust the diligence and oversight of an individual citizen. An individual who makes a decision conscious of the direct ethical, professional and legal consequences that they face without the protection of the federal government, on average, will make a better decision.

Another aspect of human nature that works at a subconscious level – the knowledge of real life consequences – or the ‘wait until your father gets home’ instinct. You better moderate your behaviour when there is a clear negative consequence linked to that behaviour.

I sign every drawing and document I approve as if my house and my kids college funds depend on it…….

So the desire to remake the system because of a single problem, one problem that overshadows an environment of incredible success, is human nature and a human failure. It is a negative aspect of a positive human trait – which is why it is so hard to resist.

I meant this article to be about the ethical aspects of the delegate system – the conflict of interest of the commercial and the compliance within a delegate’s responsibility – but there is so much at play in this single issue. I will cover that in the next newsletter.

The experience and competence of the pilot

The experience and competence of the pilot

Composite aircraft are thought to be sized to withstand ultimate load with maximum undetectable damage at 180F when saturated with humidity. In reality the structure is sized to conservative strain limits that prohibit damage growth at maximum barely visible damage at the hot wet condition and so the ultimate strength of the pristine structure at nominal service conditions usually has very high residual strength (buckling notwithstanding).

Composite aircraft are thought to be sized to withstand ultimate load with maximum undetectable damage at 180F when saturated with humidity. In reality the structure is sized to conservative strain limits that prohibit damage growth at maximum barely visible damage at the hot wet condition and so the ultimate strength of the pristine structure at nominal service conditions usually has very high residual strength (buckling notwithstanding).

The small composite aircraft had a major change to one of the wing spars at the root (for those of you who are not in the know the spar is the element of the wing that carries the bending load created by the wing lift and the root of the spar – where it meets the fuselage- carries the highest bending load.)

The small composite aircraft had a major change to one of the wing spars at the root (for those of you who are not in the know the spar is the element of the wing that carries the bending load created by the wing lift and the root of the spar – where it meets the fuselage- carries the highest bending load.) This is necessary to safeguard the public – even if the design appears to be strong enough, some level of analysis has to be done especially if the structure is one of the most critical components of the aircraft. The engineer has to be more than sure and has to prove to himself or herself (xerself?) that safety is proven.

This is necessary to safeguard the public – even if the design appears to be strong enough, some level of analysis has to be done especially if the structure is one of the most critical components of the aircraft. The engineer has to be more than sure and has to prove to himself or herself (xerself?) that safety is proven.

The Saturn 5 rocket – which is even more physically impressive, originates in a design formulated in 1962 – 56 years ago.

The Saturn 5 rocket – which is even more physically impressive, originates in a design formulated in 1962 – 56 years ago. If you go the the NASA website it is difficult to find out what they think their mission is. I am not a fan of corporate mission statements but they are useful in providing clarity of purpose when nothing else does.

If you go the the NASA website it is difficult to find out what they think their mission is. I am not a fan of corporate mission statements but they are useful in providing clarity of purpose when nothing else does. NASA has done some great work in recent years – the mars rovers are phenomenal and the data they have sent back from Mars is incredibly exciting and important. To put that in context the mars rover programs have cost $2.5Bn and have been running since 1994. Since 1994 Nasa has received (in 2018 dollars) $460Bn.

NASA has done some great work in recent years – the mars rovers are phenomenal and the data they have sent back from Mars is incredibly exciting and important. To put that in context the mars rover programs have cost $2.5Bn and have been running since 1994. Since 1994 Nasa has received (in 2018 dollars) $460Bn.

There are probably more aircraft related engineering issues that we have dealt with than driving related issues. I think the level of performance in the air, and the added safety required of that, tend to make it more difficult than anything on the ground.

There are probably more aircraft related engineering issues that we have dealt with than driving related issues. I think the level of performance in the air, and the added safety required of that, tend to make it more difficult than anything on the ground. With the wings located between the front and rear wheels under the belly of the vehicle, we knew the rear wheels would be too far aft to rotate as one would typically in a tri-gear.

With the wings located between the front and rear wheels under the belly of the vehicle, we knew the rear wheels would be too far aft to rotate as one would typically in a tri-gear. A Switchblade can be reserved at the

A Switchblade can be reserved at the