This post is taken from our free textbook “Analysis and Design of Composite & Metallic Flight Vehicle Structures” and defines a method for calculating the stresses due to an interference fit bushing.

The method in this section is referenced to (AFFDL-TR-69-42, 1986) Section 9.16. Note that several errors in the source material have been corrected. The expression for the maximum tangential stress for the bushing: The ‘p’ and ‘B’ should be in regular font, therefore the numerator becomes ‘2pB2’ and the denominator of this expression should read ‘B2-A2’.

The pressure between a lug and a bushing assembly having negative clearance can be determined by consideration of the radial displacements. This method assumes the lug acts as if it is a uniform ring around the interference fit bushing. After assembly, the increase in the inner radius of the ring (lug), plus the decrease in the outer radius of the bushing equals the difference between the radii of the bushing and ring (lug) before assembly.

![]()

Where:

δ Difference between outer radius of bushing and inner radius of the ring

u Radial displacement, positive away from the axis of the ring or bushing

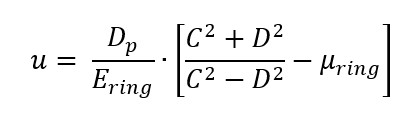

Radial displacement at the inner surface of a ring subjected to internal pressure p is:

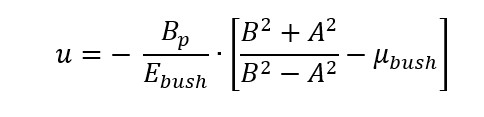

Radial displacement at the outer surface of an interference fit bushing subjected to external pressure p is:

Where:

A Inner radius of bushing, in

B Outer radius of bushing, in

C Outer radius of ring, in (lug)

D Inner radius of ring, in (lug)

E Modulus of elasticity, psi

μ Poisson’s ratio

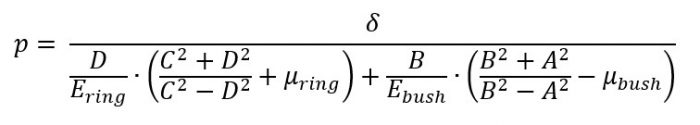

Combining these equations and substituting into the first equation and solving for p gives the following expression:

Maximum radial and tangential stresses for a ring (lug) subjected to internal pressure occur at the inner surface of the ring (lug).

Maximum radial stress for lug (the pressure on the interface between the lug and the bushing):

![]()

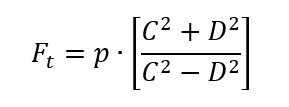

Maximum tangential stress for lug:

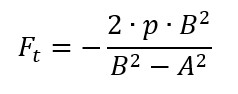

Positive sign indicates tension. The maximum shear stress at this point in the lug is:

The maximum radial stress for a bushing subjected to external pressure occurs at the outer surface of the bushing and is:

![]()

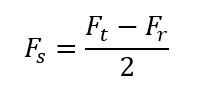

The maximum tangential stress for a bushing subjected to external pressure occurs at the inner surface of the bushing and is:

Acceptable stress levels:

- Stress corrosion. This maximum allowable press fit stress in magnesium alloys should not exceed 8000psi. For all aluminum alloys, the maximum press fit stress should not exceed 0.50Fty.

- Static fatigue. For steels heat treated to above 200ksi, where there is any risk of hydrogen embrittlement the press fit stress should not exceed 0.25Ftu.

- Ultimate strength. Ftu should not be exceeded. However, it is rare to create stresses of this magnitude in a press fit bushing installation.

A free spreadsheet for this method is available at this link

All of our free spreadsheets are available here

For Radial displacement at the outer surface of an interference fit bushing subjected to external pressure p, it seems that the equation has a subscript for p and is a little confusing. I’m assuming the numerator of the first term is B*p and no B subscript p.

Same goes for Dp in the equation above that.